No products in the cart.

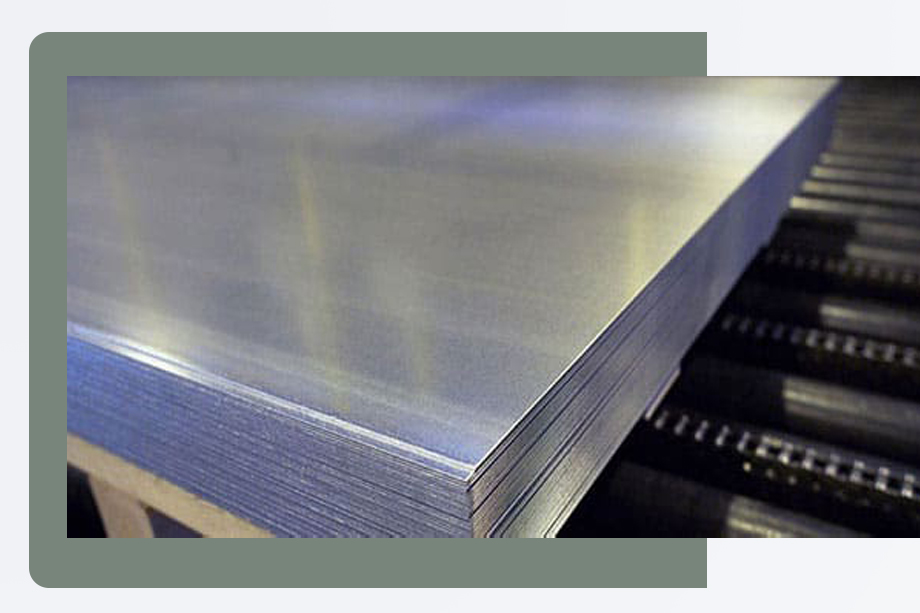

Stainless Steel Sheet 316 is one of the most widely used and popular materials in various industries. Due to its unique properties, this type of steel is extensively employed in sectors such as chemical, food, oil and gas, medical, and architecture. Key features of Steel Sheet 316 include its high corrosion resistance, ability to withstand high temperatures, and excellent mechanical properties. In this guide, we will explore the complete characteristics, applications, and advantages of using 316 Stainless Steel Sheet

Stainless Steel Sheet 316, primarily composed of iron, carbon, nickel, and chromium, is renowned for its outstanding resistance to corrosion and rust, particularly in marine and chemical environments. This exceptional property is due to its unique alloy composition, which ensures reliable performance even under harsh conditions. Additionally, Steel Sheet 316 performs excellently across a range of temperatures, making it suitable for various industrial and construction applications.

Its sleek, shiny appearance adds aesthetic value, giving projects a modern and sophisticated look. Furthermore, the ease of cutting and shaping Steel Sheet 316 makes it easier to process and implement in projects. These features make 316 Stainless Steel Sheet an excellent choice for a wide range of needs.

The price of Steel Sheet 316 varies due to several factors, including supply shortages, increased demand, market fluctuations, and inventory levels. For accurate pricing based on the weight chart of Steel Sheet 316, contact the sales team at Sahand Steel Didar. They will assist you in getting an instant quote and help you place your online order quickly.

Due to the presence of molybdenum in its chemical composition, Steel Sheet 316 exhibits exceptional corrosion resistance, particularly in chloride-containing environments and acidic conditions

Its features include high strength and hardness but lower corrosion resistance, making it more suitable for use in construction, building industries, and machinery parts manufacturing

It contains various alloying elements to enhance its mechanical properties. It is primarily used in the oil and gas industry, automotive industry, and in the manufacturing of heat-resistant components

High resistance to heat and elevated temperatures is one of the key features of this type of sheet. Its applications include the petrochemical industry, power plants, and furnace manufacturing

High resistance to heat and elevated temperatures is a key feature of this type of sheet. Its applications include the petrochemical industry, power plants, and furnace manufacturing

316 and 304 Stainless Steel Sheets are two of the most commonly used types of stainless steel. However, 316 Stainless Steel Sheet offers higher corrosion resistance due to the presence of molybdenum in its chemical composition, especially in chloride-rich environments. This makes 316 Stainless Steel Sheet more suitable for use in harsher conditions. Additionally, 316 Stainless Steel Sheet has better resistance to high temperatures.

On the other hand, 304 Stainless Steel Sheet, due to its lower cost, is typically used in environments where high corrosion resistance is not critical. Therefore, the choice between 316 and 304 Stainless Steel Sheets depends on the specific application and environmental conditions

All rights reserved for Sahand Steel Didar. Any unauthorized copying or reproduction will be subject to legal action